The most often used tool magnets are rubber coated magnets, sometimes referred to as waterproof magnets.With a long-lasting rubber plastic coating, these neodymium rubber coated magnets are strong rare earth magnets. Applications where the surface may be readily scraped or damaged are particularly well-suited for them. Now, let's examine the types and benefits of rubber-coated magnets in more detail.

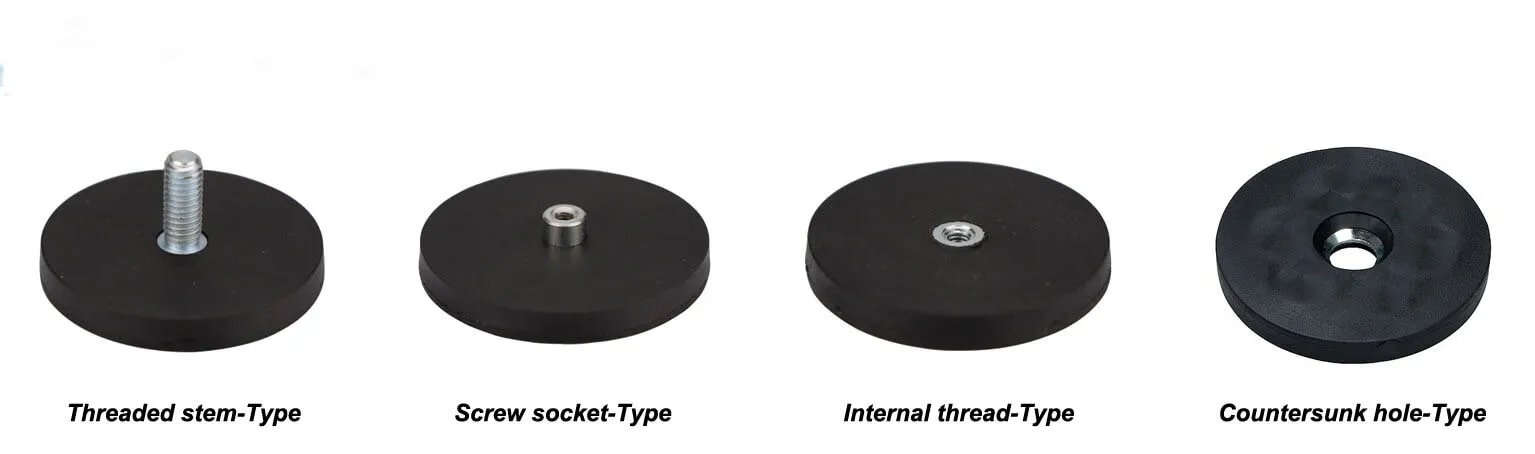

Rubber coated magnets mainly include the following types:

1. Threaded Stem-Type Rubber Coated Magnet

2. Screw Socket-Type Rubber Coated Magnet

3. Internal Thread-Type Rubber Coated Magnet

4. Countersunk Hole-Type Rubber Coated Magnet

The friction between the rubber and the steel surface, to which the magnet is connected, prevents chipping and corrosion, and the rubber plastic coating also offers exceptional slide resistance. Rubber magnets are used by industrial designers and manufacturers as a holding and fastening tool. They work great outdoors as well as in aquariums and construction sites. Certain plastic-coated mounting magnets have a centrally located threaded hole (female thread) for bolt attachment, or a centrally located threaded stud (male thread) for hook or eye bolt insertion. Additionally, we offer rubber magnets with pre-drilled holes that are fastened with screws or nails.

Rubber-coated magnets have a strong magnetic field and are waterproof, making them perfect for both indoor and outdoor uses where a strong draw force is required but surface protection is also essential.